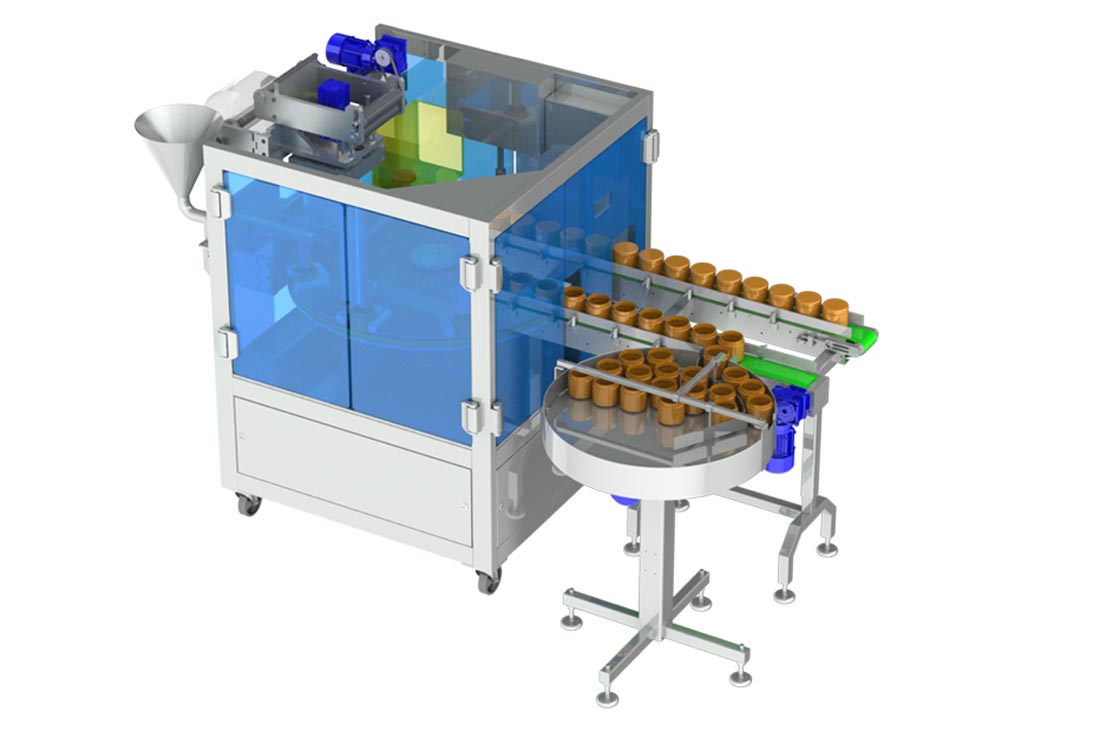

NR10

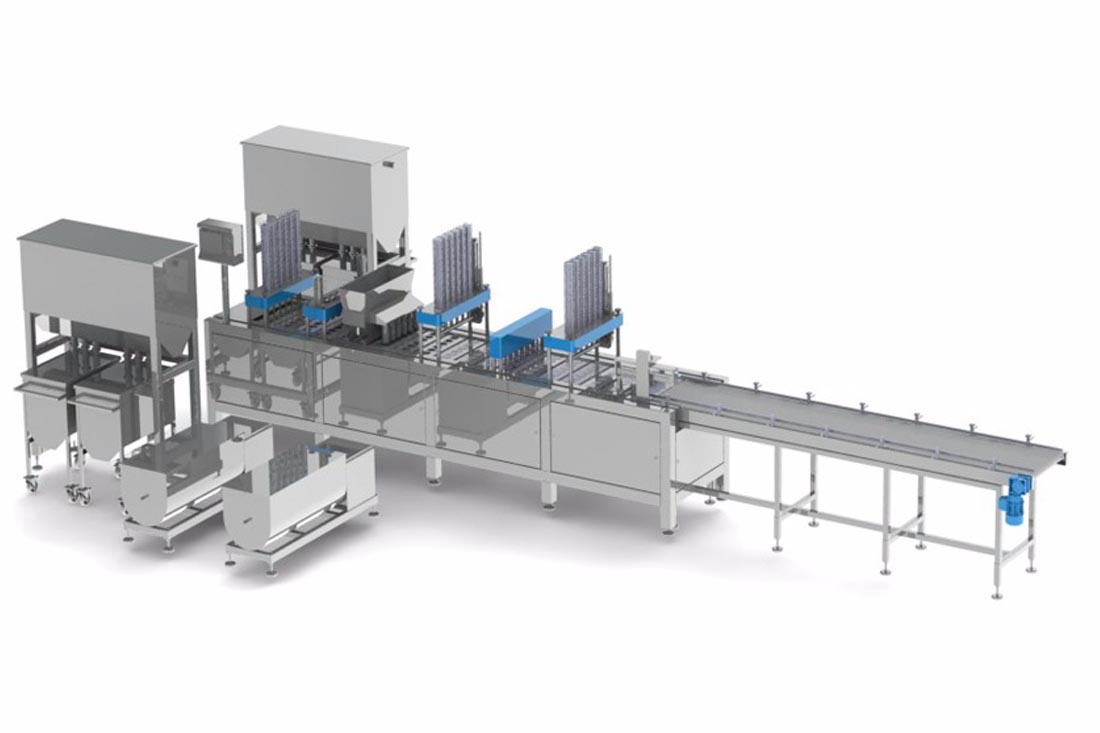

filling and sealing machine - single and twin track

Description

Designed for the packaging of stackable containers for liquid, semi-liquid and creamy products.

Easy to manage even by unskilled operators. Very low maintenance costs

Different packaging models can be packaged on the same machine thanks to the simple and fast format change.

Great versatility, real highlight of our rotating models and wide range of accessories available

Designed for products such as yoghurt, ice-cream, juice, milk salads, dressings, dips, spreadable cream as well as novelties or dessert

Special version for packaging Calippo®The basic equipment includes:

- Cup dispenser (max. diam. 180 mm.)

- Volumetric and/or time-elapse dosers

- Lid dispenser (tab lids, pre-punched aluminium foil , film from reel, snap-on lids)

- Powered extraction belt

Options:

- additional dosing stations

- special injectors

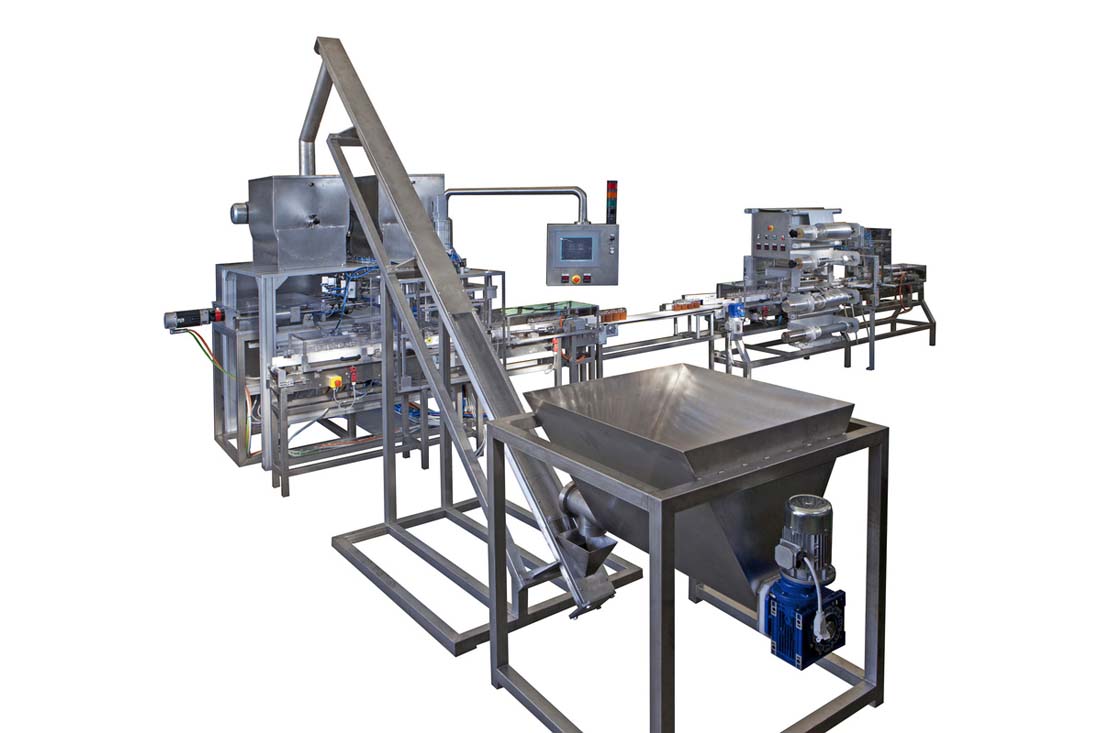

- hoppers

- feeders , sorters and pick&place systems

The standard equipment is integrated from time to time, according to the specific needs of the customer, with additional dosing stations, special injectors, hoppers, feeding systems and manipulators.

Full stainless steel wheeled structure and safety panels.

Electrical panel, touch screen, PLC and Siemens logic.

Speed : from 500 to 2000 pcs/hour

Also available in vacuum and / MAP version

Gallery

Applications

| Food |

|---|

| yoghurt, milk, cream, mayonnaise, sauces, meat sauce, chocolate spread, jams, oil, syrup, margarine, ice cream, cheese spreads, creams, honey |